CFI Electric Ltd

Electric Heat Tracing Services in Ontario

Electric Heat Tracing: Smart Temperature Management for Your Infrastructure

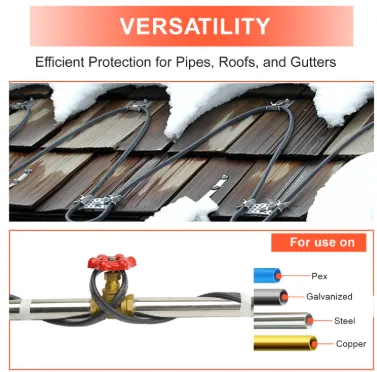

Electric heat tracing is a proven solution for protecting pipes, roofs, gutters, and critical infrastructure from freezing during harsh Canadian winters. At CFI Electric Ltd, we design and install electric heat tracing systems that actively manage temperature where insulation alone cannot. This approach delivers reliable freeze protection, controlled heat output, and long-term system performance for residential, commercial, and industrial properties.

What Electric Heat Tracing Is and Why It Is Used

Electric heat tracing is an engineered heating method that uses electrically powered heating cables installed directly onto pipes, surfaces, or structures. These cables generate controlled heat to offset heat loss and maintain safe operating temperatures during cold conditions.

Unlike passive insulation, electric heat tracing responds to temperature changes in real time. This makes it an effective solution for freeze protection, snow and ice control, and temperature maintenance across a wide range of applications in Ontario.

How Electric Heat Tracing Systems Work

An electric heat tracing system is made up of several components that operate together to deliver consistent and safe heating. Each part plays a specific role in system performance.

Heating Cables

Electric heat tracing cables may be self-regulating or constant wattage. Self-regulating cables automatically adjust their heat output based on surrounding temperatures, reducing energy use and the risk of overheating.

Power Connection Kits

These components safely connect the electric heat tracing cable to the electrical supply while maintaining proper grounding and strain relief.

Controls and Sensors

Thermostats and temperature sensors monitor surface or ambient conditions and activate the electric heat tracing system only when heating is required.

End Seals and Splices

Proper termination and splicing protect the cable from moisture and physical damage and are essential for long-term reliability.

Common Electric Heat Tracing Applications

Electric heat tracing is used wherever freezing, ice buildup, or temperature loss can cause damage, downtime, or safety concerns. Below are the most common environments where electric heat tracing is installed.

Industrial Facilities

Electric heat tracing is critical for pipelines in oil and gas operations, as well as chemical, food, and pharmaceutical processing facilities where maintaining product flow and viscosity is essential.

Commercial Buildings

Commercial properties use electric heat tracing for freeze protection of water lines and for roof and gutter de-icing systems that reduce ice dams and falling ice hazards.

Residential Properties

Homeowners rely on electric heat tracing to protect exposed water pipes, prevent roof and gutter ice buildup, and support underfloor heating systems in specific areas.

Specialized Infrastructure

Electric heat tracing is also used in water treatment plants, sewage systems, and agricultural environments such as greenhouses where temperature stability is required.

Benefits of Electric Heat Tracing for Property Owners

Electric heat tracing provides practical advantages that reduce risk and long-term costs, especially in cold climates.

Reliable Freeze Protection

Electric heat tracing helps prevent burst pipes, water damage, and structural issues caused by freezing temperatures.

Consistent Temperature Control

Electric heat tracing maintains steady temperatures on pipes, roofs, driveways, parking ramps, and gutters, allowing snow and ice to melt efficiently.

Energy-Efficient Operation

Self-regulating electric heat tracing systems heat only when needed, reducing unnecessary power consumption compared to traditional heating methods.

Low Maintenance Requirements

With no boilers, steam systems, or moving mechanical parts, electric heat tracing systems typically require minimal maintenance and offer long service life.

Why Professional Electric Heat Tracing Installation Matters

Electric heat tracing systems must be properly designed and installed to perform safely and efficiently. Incorrect cable selection, spacing, or termination can result in poor performance, excessive energy use, or electrical hazards.

Professional installation ensures electric heat tracing systems comply with the Ontario Electrical Safety Code. Licensed electricians also perform proper testing and commissioning, helping ensure long-term reliability and warranty protection. CFI Electric Ltd installs electric heat tracing systems with a focus on safety, performance, and durability.

Our Electric Heat Tracing Process for Homeowners

For residential electric heat tracing projects, our approach is clear and methodical to ensure the system meets both safety and performance requirements.

Property Assessment

We visit your home to identify areas that would benefit from electric heat tracing, such as roofs, gutters, downspouts, and exposed water pipes.

System Design and Material Calculation

A Master Electrician determines the appropriate cable type, insulation considerations, and total material requirements based on your property and usage needs.

Quotation and Scheduling

You receive a no-cost quote along with a clear installation timeline outlining how long the electric heat tracing installation will take from start to finish.

Our primary focus is electric heat tracing installations for roofs with shallower slopes, gutters and downspouts, and residential water piping systems prone to freezing.

STILL NOT SURE?

Frequently Asked Questions

What Is Electric Heat Tracing Most Commonly Used For?

Electric heat tracing is most often used for freeze protection of pipes, roof and gutter de-icing, and temperature maintenance in commercial and industrial systems.

Is Electric Heat Tracing Energy Efficient?

Yes. Modern electric heat tracing systems, especially self-regulating types, reduce energy use by adjusting heat output based on ambient conditions.

Can Electric Heat Tracing Be Added to Existing Systems?

In many cases, electric heat tracing can be retrofitted to existing pipes or roofs if the surfaces and electrical supply meet safety requirements.

Is Electric Heat Tracing Safe for Residential Properties?

When installed by licensed professionals and designed to meet electrical codes, electric heat tracing is a safe and dependable solution for homes.

How Long Does an Electric Heat Tracing System Last?

With proper design, installation, and inspection, electric heat tracing systems can operate reliably for many years with minimal maintenance.

COntact us

Schedule Electric Heat Tracing Installation

If freezing temperatures are putting your property at risk, electric heat tracing offers a dependable and efficient solution. Contact CFI Electric Ltd to discuss electric heat tracing options, schedule an assessment, and receive a clear, professional quote.

SERVICES

HELPFUL LINKS

CONTACT INFORMATION

Phone: (416) 575-9999

Location: Oshawa, ON L1H 4E1

Master Electrician License #6002110 ESA Contractor: 7001418

ECRA: MCR 1290

Your privacy is extremely important to us. The trust placed in us by our customers is absolutely essential to our success. We understand that and do all we can to earn and protect that trust. We do not share, sell, loan or use your personal information with any outside companies or third parties without your consent. We will use your personal information as needed when communicating with ESA (Electrical Safety Authority) and/or the local hydro utility (such as Toronto Hydro, Alectra, Oakville Hydro, etc...) to pull out permits, organize inspections and ensure that our work is compliant with OBC and OESC for your property.

@ Copyright 2025 • CFI ELECTRIC LTD. • All Rights Reserved